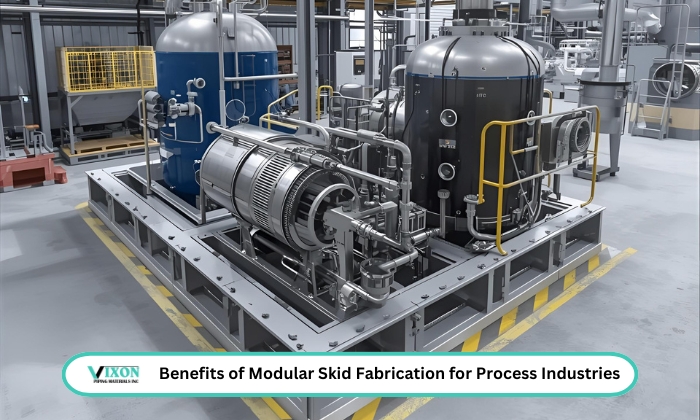

In today’s fast-paced industrial landscape, process industries are increasingly turning to modular skid fabrication as a smarter alternative to traditional on-site construction. Skid fabrication involves pre-assembling equipment, piping, and control systems onto a structural frame (or “skid”) in a controlled workshop environment. These modular units are then delivered ready for immediate integration at the plant site. This not only streamlines installation but also minimizes site disruptions, enhances safety, and improves overall project efficiency. From oil & gas to pharmaceuticals and water treatment, industries across the board are leveraging this method to meet modern demands for quality, speed, and reliability.

Introduction to Skid Fabrication

Skid fabrication is a process where equipment, piping, instruments, and control systems are assembled onto a compact, self-contained steel base known as a “skid.” These units are built and tested off-site in a controlled facility, then transported to the final installation location as a complete system. This method ensures faster deployment and reduces the time and work needed on the job site. Because of its convenience and efficiency, skid fabrication is gaining popularity across various industries. It is widely used in oil & gas, pharmaceuticals, food processing, and water treatment sectors. These industries value modular skids for their clean design, simple integration, and ability to meet strict regulatory and performance standards.

Why Process Industries are Adopting Skid Fabrication

Traditional on-site construction often comes with delays, safety risks, and space limitations. Projects can be slowed down by bad weather, labor shortages, or unexpected site issues. Working in confined or active plant areas also increases hazards for workers and limits access for large equipment setups.

Modular skid systems help solve many of these problems. Since fabrication happens off-site, project schedules become easier to manage. Weather delays are reduced, and critical systems are built under controlled conditions. Safety improves as fewer people and less heavy equipment are needed at the main site.

Skid fabrication supports faster, safer, and more efficient project delivery. It helps process industries keep up with production needs while reducing downtime and installation stress.

Key Benefits of Modular Skid Fabrication

Reduced On-Site Construction Time

Modular skid units are built and tested off-site. This reduces the need for time-consuming work at the main plant. Weather delays, site access issues, and permit holdups are minimized. Once the skid arrives, it’s ready to install, which shortens project timelines and speeds up production start.

Improved Quality and Testing Control

Factory conditions provide a cleaner, more stable environment for welding, assembly, and inspections. This results in higher build quality. Factory Acceptance Testing (FAT) can be done before shipment, ensuring the system works as expected. This lowers the chance of problems during installation.

Enhanced Safety for Workers

Off-site fabrication lowers the number of workers needed on the main site. This reduces the risk of accidents in busy or hazardous areas. Less equipment movement and fewer people on-site help keep the workspace safer and more organized.

Cost-Effectiveness Over Project Lifecycle

By shifting labor off-site, companies save on on-site labor costs. Installation is quicker, which means less downtime. The controlled build process reduces rework. Long-term, these systems often require less maintenance and result in fewer shutdowns, saving money across the project’s life.

Compact and Space-Efficient Design

Modular skids are built to make the best use of space. Components are arranged efficiently, making them ideal for plants where floor space is limited. This compact layout helps reduce the overall footprint without cutting performance.

Easy Transportation and Installation

Skids are designed for simple transport. Units can be lifted and moved as a whole, reducing the need for heavy site work. Once on-site, they can be connected quickly with minimal effort. Many systems work as plug-and-play, speeding up the setup process.

Scalability and Flexibility

Skid systems can grow with demand. New skids can be added or old ones replaced without major changes to the main plant. This makes them ideal for facilities looking to expand or adjust to new process needs. Standardized design also helps maintain consistency across multiple locations.

Industries That Benefit Most from Skid Fabrication

Modular skid fabrication offers advantages that align perfectly with the demands of several high-performance sectors. From reducing downtime to ensuring compliance with strict sanitary standards, these pre-assembled systems bring versatility and efficiency to a wide range of industries.

Oil & Gas

In the oil & gas industry, time is money. Modular skids enable quicker installation and integration into existing infrastructure, helping reduce costly downtime during upgrades or expansions. For example, a refinery can install a pre-tested chemical injection skid without halting operations. Skid fabrication also improves safety by moving complex welding and assembly away from hazardous on-site zones.

Pharmaceuticals

Pharmaceutical production requires sterile and controlled environments. Skid-mounted systems are built in compliance with GMP (Good Manufacturing Practices) and can be designed for easy installation into cleanrooms. Their compact and organized layouts are ideal for limited space in high-specification labs. A biopharma company, for instance, might use skids for vaccine formulation lines, ensuring fast deployment and validated system performance.

Food and Beverage

Sanitary construction is critical in food-grade processing. Modular skids are fabricated using materials like stainless steel and designed with hygienic finishes and easy-clean access. Fast installation limits production interruptions. A beverage bottling plant could benefit from installing a CIP (Clean-in-Place) skid that’s plug-and-play, enabling rapid sanitation between production runs.

Water Treatment

Skid systems offer fully pre-assembled and tested solutions for water purification, filtration, and chemical dosing. Their quick deployment is particularly valuable for municipalities or industrial sites that require immediate treatment capacity. For example, a remote mining operation might install a containerized water treatment skid to meet urgent environmental compliance needs.

Power Plants

In both conventional and renewable power sectors, skids support fuel management, water injection, and chemical dosing systems. Their standardized, compact design simplifies integration into new or retrofitted systems. A gas-fired power station might use modular skids to optimize water-softening processes, helping reduce scale buildup and extend equipment life.

Skid Fabrication vs. Traditional Field Fabrication

When it comes to building complex process systems, businesses must choose between traditional field fabrication and modern skid fabrication. Understanding the core differences between these two approaches helps highlight why many process industries are making the shift toward modular, skid-based solutions. Below is a direct comparison based on key project factors:

1. Time Efficiency

Traditional Field Fabrication:

Involves assembling equipment directly at the site, often leading to delays due to weather, site readiness issues, or logistical complications.

Skid Fabrication:

Entire systems are pre-assembled off-site in a controlled workshop environment, significantly reducing on-site construction time. Projects benefit from parallel work streams—site prep and module fabrication can happen simultaneously.

2. Labor Requirements

Traditional Field Fabrication:

Requires large on-site labor teams for installation, increasing supervision needs and the risk of coordination problems.

Skid Fabrication:

Utilizes smaller, highly skilled fabrication teams off-site. On-site labor is minimized, lowering overall workforce management challenges and related costs.

3. Safety Considerations

Traditional Field Fabrication:

Poses higher safety risks due to crowded worksites, exposure to live systems, and challenging environmental conditions.

Skid Fabrication:

Enhances safety by shifting fabrication to a controlled setting, reducing worker exposure to hazards. Site congestion is also minimized during installation.

4. Quality and Testing

Traditional Field Fabrication:

On-site conditions can vary, often affecting weld quality, inspection processes, and testing reliability.

Skid Fabrication:

Offers higher quality control through standardized procedures in a clean, regulated workshop. Systems undergo Factory Acceptance Testing (FAT) before reaching the site.

5. Modularity and Scalability

Traditional Field Fabrication:

Custom-built systems may be difficult to scale or replicate across multiple sites.

Skid Fabrication:

Modular skids are designed for replication and easy expansion. Companies can scale operations by adding standardized skid units as needed.

6. Cost Implications

Traditional Field Fabrication:

Often involves higher and less predictable costs due to delays, rework, and extensive labor.

Skid Fabrication:

Offers better cost control through streamlined production, faster commissioning, and lower on-site installation expenses.

How to Choose a Reliable Skid Fabrication Partner

When selecting a skid fabrication partner, prioritize companies with solid experience in your industry, whether oil & gas, pharmaceuticals, or water treatment. Look for strong engineering and testing capabilities, including design expertise and Factory Acceptance Testing (FAT) to ensure quality. Verify that the partner holds recognized certifications like ISO and ASME, which demonstrate commitment to industry standards. The ability to customize skid designs to your specific needs is important for operational efficiency. Also, ensure the partner provides thorough documentation and ongoing support to assist throughout the project lifecycle.

Conclusion

Modular skid fabrication offers clear advantages for process industries, including faster installation, improved safety, better quality control, and cost savings. Its compact, flexible design suits a range of sectors, helping streamline operations while reducing risks and downtime. Consider modular skid solutions for your next project to improve speed, safety, and reliability.